A. Qo'lda yuklash

Blender qopqog'ini oching va materiallarni to'g'ridan-to'g'ri qo'lda yuklang yoki qopqoqda teshik qiling va materiallarni qo'lda qo'shing.

B. Vintli konveyer orqali

Vintli oziqlantiruvchi kukun va granulalarni bir mashinadan boshqasiga o'tkazishi mumkin. Bu samarali va qulay. Ishlab chiqarish liniyasini shakllantirish uchun qadoqlash mashinalari bilan hamkorlikda ishlashi mumkin. Shunday qilib, qadoqlash liniyasida, ayniqsa yarim avtomatik va avtomatik qadoqlash liniyasida keng qo'llaniladi. U asosan sut kukuni, oqsil kukuni, guruch kukuni, sutli choy kukuni, qattiq ichimlik, qahva kukuni, shakar, glyukoza kukuni, oziq-ovqat qo'shimchalari, ozuqa, farmatsevtika xom ashyosi, pestitsid, bo'yoq, lazzat, xushbo'y moddalar va boshqalar kabi kukunli materiallarni tashishda qo'llaniladi.

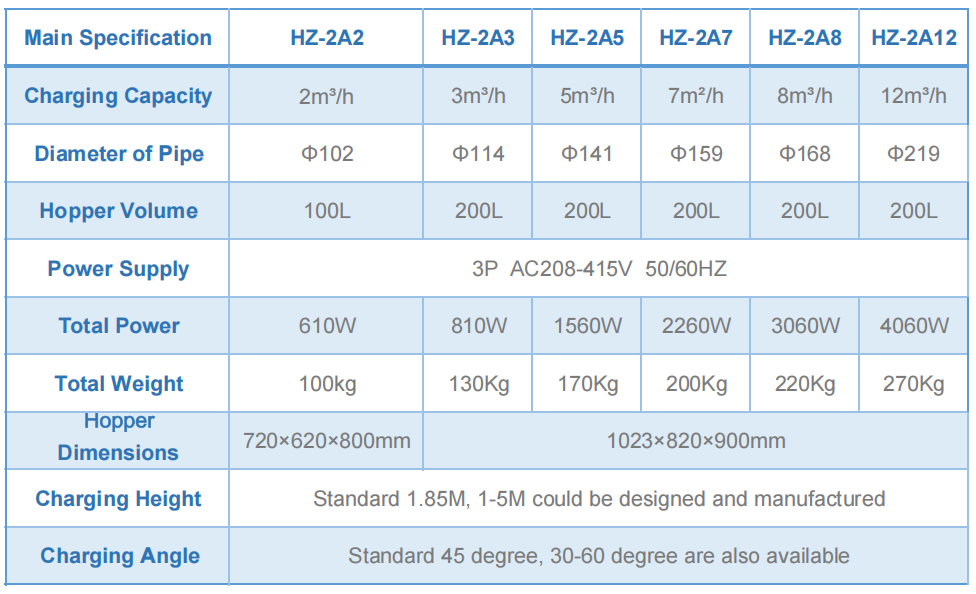

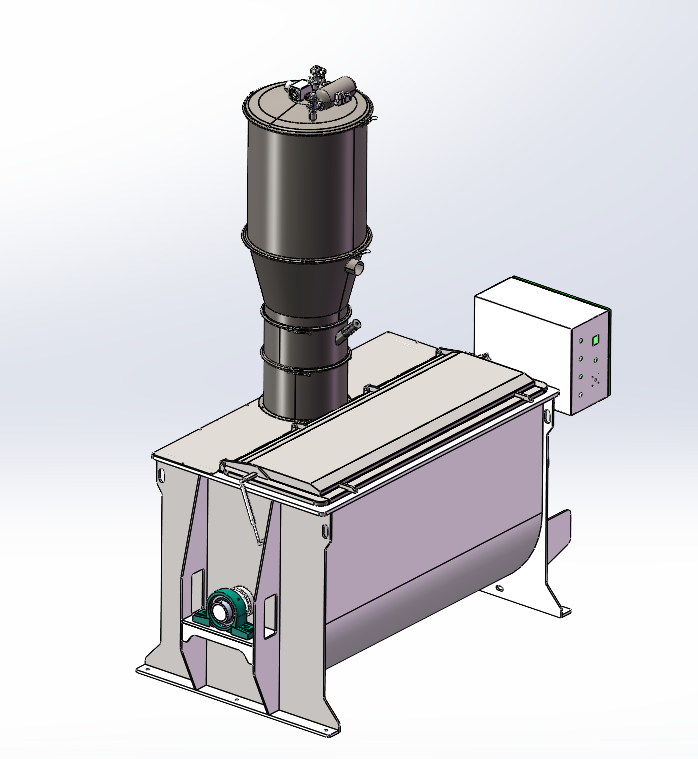

Vintli konveyer oziqlantiruvchi vosita, vibrator dvigateli, huni, quvur va vintdan iborat. 45 daraja zaryadlash burchagi va 1,85 m zaryad balandligi bilan standart model. Imkoniyatlar 2m3/soat,3m3/soat,5m3/soat,8m3/soat va hokazo tezlikka ega. Boshqalar moslashtirilishi mumkin.

Ish printsipi:

Vintli oziqlantiruvchi mahsulotni to'liq yopiq spiral aylanadigan mil orqali yuqoriga ko'taradi. Vint tanasining tezligi oddiy vintli konveyerdan yuqori. Santrifüj kuchi ta'sirida uzatiladigan material va korpus ishqalanish hosil qiladi, bu materialning vint pichog'i bilan aylanishiga to'sqinlik qiladi va materialning muammosini bartaraf qiladi. Gravitatsiyaning tushishi, shu bilan materiallarning eğimli yoki vertikal tashishini amalga oshirish.

C.Vakuumli konveyer orqali

Vakuumli oziqlantiruvchi qurilma havo chiqaradigan jakuzili havo nasosidan foydalanadi. Absorbsion materialning kirish qismi va butun tizim vakuum holatida bo'lishi kerak. Materialning chang donalari atrof-muhit havosi bilan material kraniga so'riladi va material bilan oqadigan havo bo'lib hosil bo'ladi. Absorbsion material trubkasidan o'tib, ular bunkerga etib kelishadi. Unda havo va materiallar ajratiladi. Ajratilgan materiallar qabul qiluvchi material qurilmasiga yuboriladi. Boshqaruv markazi materiallarni oziqlantirish yoki tushirish uchun pnevmatik uch valfning "yoqish / o'chirish" holatini nazorat qiladi.

Vakuumli oziqlantiruvchi qurilmada siqilgan havo qarshisidagi puflash moslamasi o'rnatilgan. Materiallarni har safar bo'shatishda siqilgan havo zarbasi filtrni qarama-qarshi tomondan uradi. Filtr yuzasiga yopishtirilgan kukun materialni normal singdirishini ta'minlash uchun puflanadi.

Pnevmatik vakuum oziqlantiruvchi vakuum generatori orqali yuqori vakuumli vakuumli havo yordamida materiallarni etkazib berishga erishish uchun mexanik vakuum pompasi yo'q, oddiy tuzilishga ega, kichik o'lchamli, texnik xizmat ko'rsatmaydi, past shovqin, nazorat qilish oson, materialning statikligini yo'q qiladi va GMP talablariga muvofiq va hokazo. tanlangan oziqlantirish qurilmasi.

Vintli konveyer va vintli oziqlantiruvchini solishtirish

Vakuumli oziqlantiruvchining afzalliklari asosan quyidagilarni o'z ichiga oladi:

1) Changsiz yopiq quvurlarni tashish changning ifloslanishini samarali ravishda kamaytirishi va ish muhitini yaxshilashi mumkin. Shuningdek, u atrof-muhit va xodimlarning materiallarga ifloslanishini kamaytiradi va tozalikni yaxshilaydi.

2) Kam joy egallaydi, kichik joylarda changni tashishni yakunlashi mumkin, bu esa ish joyini chiroyli va saxovatli qiladi.

3) Uzoq yoki qisqa masofa bilan cheklanmagan, ayniqsa uzoq masofalarga tashish uchun javob beradi.

4) Qo'l mehnati zichligini kamaytirish va ish samaradorligini oshirish. Ko'pgina chang materiallarini tashish usullari uchun birinchi tanlovdir.

Kamchiliklarga quyidagilar kiradi:

1)Juda nam, yopishqoq yoki juda ogʻir materiallarni tashish uchun mos emas.

2)Materiallarning tashqi o'lchamlari va zichligiga qo'yiladigan talablar nisbatan qat'iydir. Turli xil shakllar yoki zichlikdagi materiallar uchun tashish sifati sezilarli darajada yomonlashishi mumkin.

Vintli oziqlantiruvchilarning afzalliklari quyidagilardan iborat:

1)Materiallarning tashqi o'lchamlari va zichligiga qo'yiladigan talablar nisbatan erkindir. Materiallar spiralga muammosiz kirishi mumkin ekan, ular asosan farq qilmasdan baland joylarga ko'chirilishi mumkin.

2)Material turlarini o'zgartirganda tozalash unchalik qiyin emas va vakuumli oziqlantiruvchiga qaraganda oddiyroq.

Asosiy kamchiliklari quyidagilardir:

1)Olis masofalarga tashish uchun mos emas, chunki masofa oshgani sayin uning tashish samaradorligi pasayadi.

2)Kukun yoki uchuvchi materiallar changning ifloslanishiga olib kelishi mumkin.

Shunday qilib, vakuumli oziqlantiruvchilar va vintli oziqlantiruvchilarning har birining o'ziga xos stsenariylari va cheklovlari mavjud. Qaysi oziqlantiruvchini tanlash uchun o'ziga xos moddiy xususiyatlar, ishlab chiqarish muhiti va ishlab chiqarish samaradorligi talablari kabi omillarga asoslangan holda har tomonlama ko'rib chiqilishi kerak.

Agar sizda lenta blenderining printsipi bo'yicha qo'shimcha savollaringiz bo'lsa, maslahat uchun biz bilan bog'laning. Aloqa ma'lumotlaringizni qoldiring va biz sizga yordam berish va shubhalaringizni aniqlashtirish uchun 24 soat ichida siz bilan bog'lanamiz.

Yuborilgan vaqt: 06-2025-yil